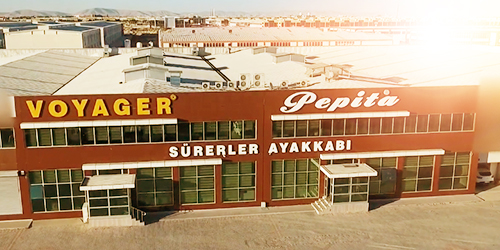

The easiest part of the shoes is to wear. Making shoes at Voyager is a work that requires art and is not as simple as it looks, requires effort and requires patience. As Voyager family, we attach importance to our R & D studies in order to meet your shoes need since our establishment.

In our new facilities, we do what is necessary to provide better service to our valued customers and we strive to produce a comfortable product for you.

The most important thing for shoe modeling is to determine the model. This model varies according to the specification, that is, the segment you will address.

The number and lining of the shoe is appropriately cut from animal skin, fabric or artificial leather.

It is the upper part of the shoe which is formed by stitching the pieces in different form, except the sole. It can be produced on contract basis.

The parts forming the upper and the lining are sewn together.

Lacing holes are made at this stage. Number v model embossing is also made on the inner surface of the shoe.

Heels are also prepared with inner and outer sole parts.

Parçaların eklenmesi ile oluşan saya kalıbının üzerine gerilir daha sonra ise iç tabana dikilir ya da çivilerle tutturularak kalıp haline getirilir.

The upstream and insole should be held in the mold until it becomes permanent.

Burning of yarns damaged or seen as redundant during the production process is the necessary stage for cleaning.

With the awareness of sustainable life responsibility, Voyager Shoes aims to make sustainable natural resources conservation by reducing the use of raw materials and energy by making technological improvements in environmentally friendly production and productivity.

Commit to regulate and comply with environmental management system requirements.